In the rapidly growing karting industry, exceptional products rely on advanced manufacturing systems. The KUPAO KARTING Production Base stands as a leading force in the sector, thanks to its specialized end-to-end production system and strict quality control throughout the entire process. Every step—from R&D to final delivery—is built on a foundation of innovative technology and meticulous craftsmanship.

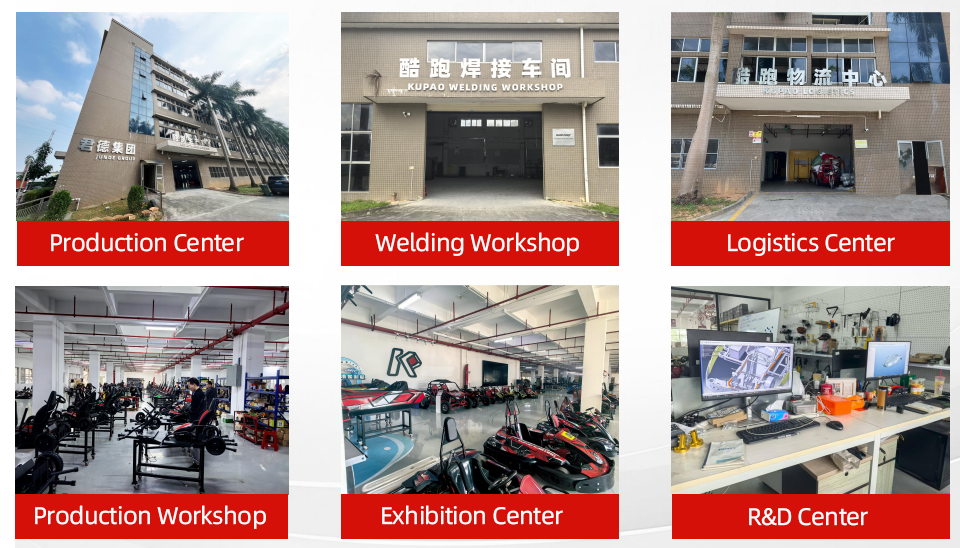

Spanning 20,000 square meters, the self-contained production base integrates R&D, manufacturing, testing, exhibition, and logistics. It includes dedicated zones such as the welding workshop, production workshop, R&D center, exhibition hall, and smart logistics center. Additionally, the facility features an off-road test track, employee dormitories, and dining areas—creating a modern and human-centric production campus.

Smart Manufacturing, Precision Welding

Welding is a core process in kart manufacturing, directly impacting vehicle safety and durability. KUPao’s welding workshop utilizes high-precision machinery and automated intelligent equipment to achieve accurate welding of critical structural components. This ensures every kart delivers outstanding structural rigidity and safety. The workshop not only guarantees high efficiency and quality but also supports large-volume order fulfillment.

End-to-End In-House Production, Integrated Quality Control

The KUPAO production base maintains full in-house control from development to delivery:

- The R&D center drives continuous product innovation and technological upgrades.

- The production workshop is equipped with advanced lines for flexible manufacturing.

- The welding workshop focuses on building strong and reliable chassis structures.

- The exhibition center showcases product excellence and brand culture.

- The smart logistics center ensures accurate and efficient order shipments.

- The test track validates each kart’s performance and safety through professional road simulations.

KUPAO has brought together a team of over 150 engineers and service specialists across design, engineering, manufacturing, operations, and after-sales support. Together, they form a closed-loop system that ensures consistency from production to service. To date, KUPAO has sold more than 3,000,000 karts and serves over 50,000 store members, with continuously expanding market coverage and user satisfaction.

The KUPAO KARTING Production Base is not just a manufacturing site—it is a hub of technological accumulation, quality refinement, and brand building. Moving forward, KUPAO will continue to leverage its end-to-end system to deliver safer, more professional, and more thrilling driving experiences to karting enthusiasts worldwide.

KUPAO KARTING—End-to-End Smart Manufacturing, Empowering Speed and Passion.